Optimization: power-transmission

1 - Introduction

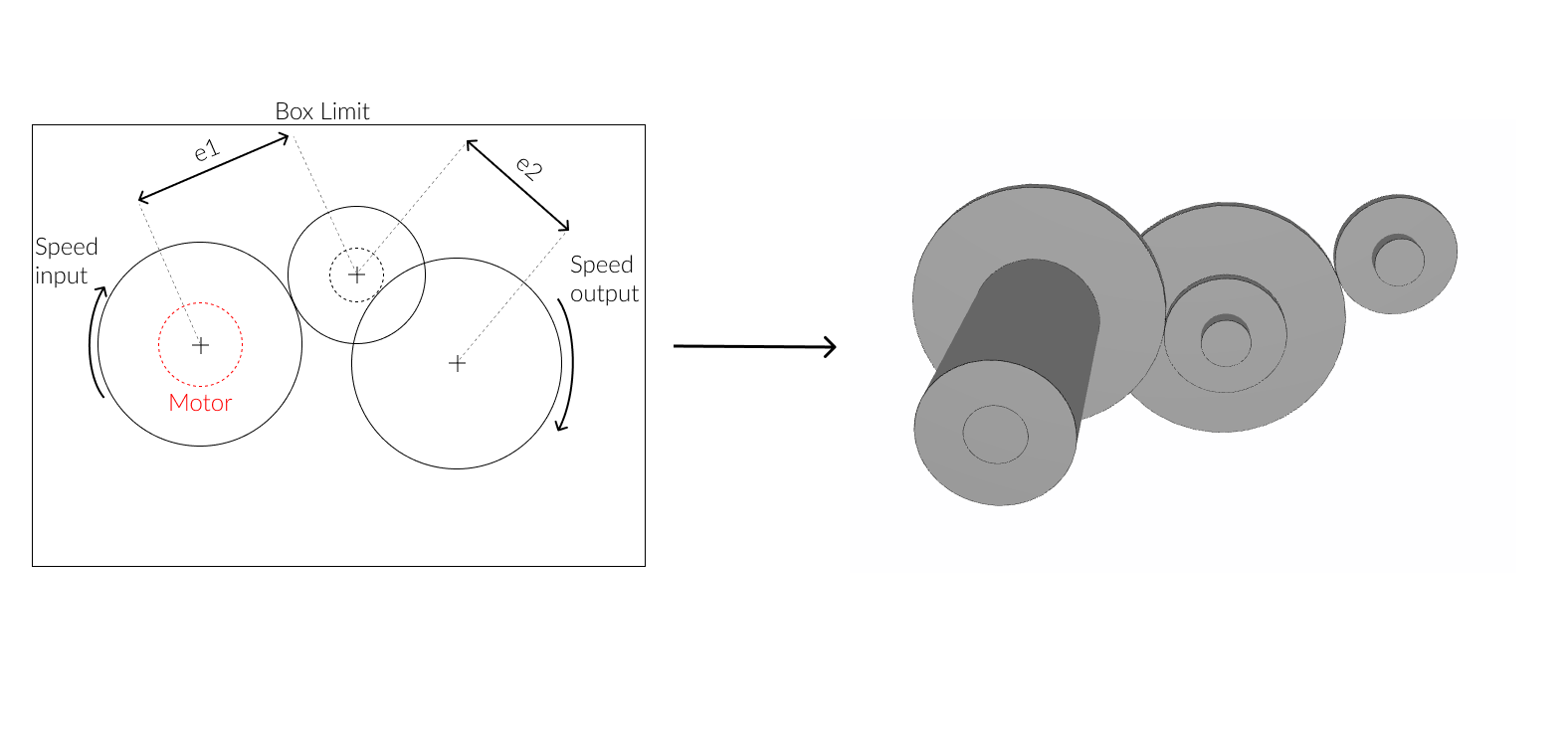

The goal of this tutorial is to understand how the optimization works in our modules and how to create an optimized bot. Let's take a simple case: the construction and optimization of a simple reductor made of 3 shafts, 4 gears and 1 motor.

In this example, we want to optimize the mass of this reductor that meets a couple specifications:

- The ratio between the input and the output speed is imposed

- The reductor must fit into a box that is imposed

The paramaters that the bot will optimize are the axial distances e1 and e2 and the diameter of each gear.

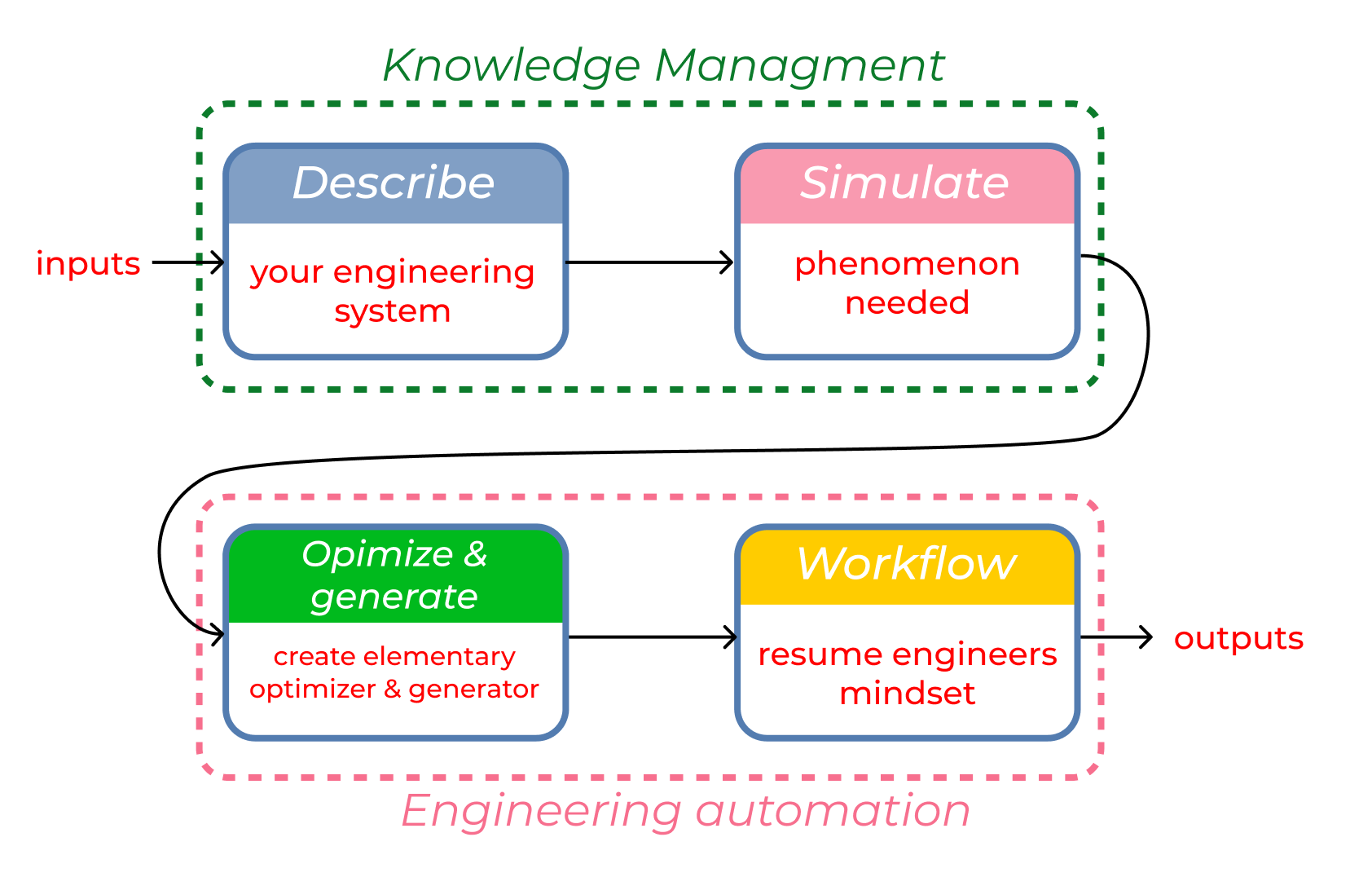

2 - Build the bot in 4 steps

The bot creation follows four steps. In this tutorial, each step will be described to help you understand how you can apply these four steps for a new bot.

Before beginning, you have access to tutorial2 in the tutorials folder cloned as explained in the first tutorial.

2.1 - Describe your engineering system

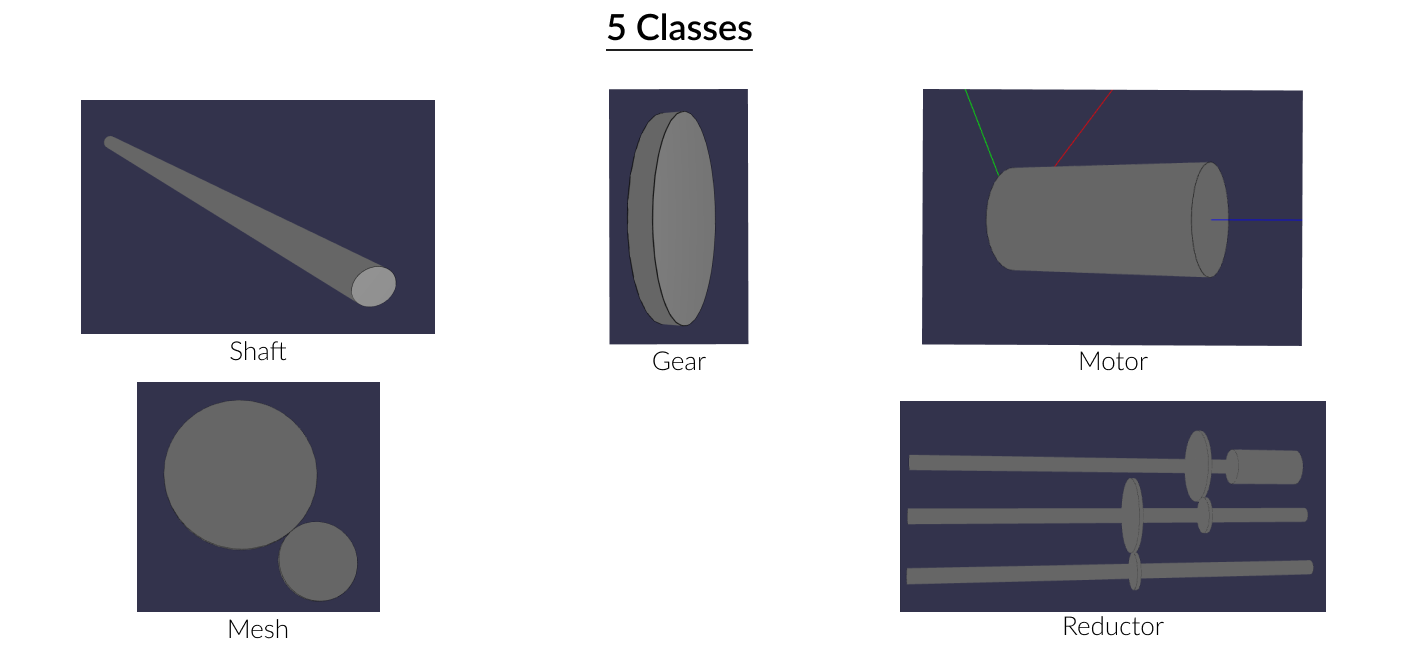

First of all, several python classes are written to define different objects that modelize the reductor along with all its components such as gears, shafts and motor.

Linking those objects is done by a Mesh class that represents the meshing between two gears.

All the classes presented in this part need to be coded in a same python file called core.py.

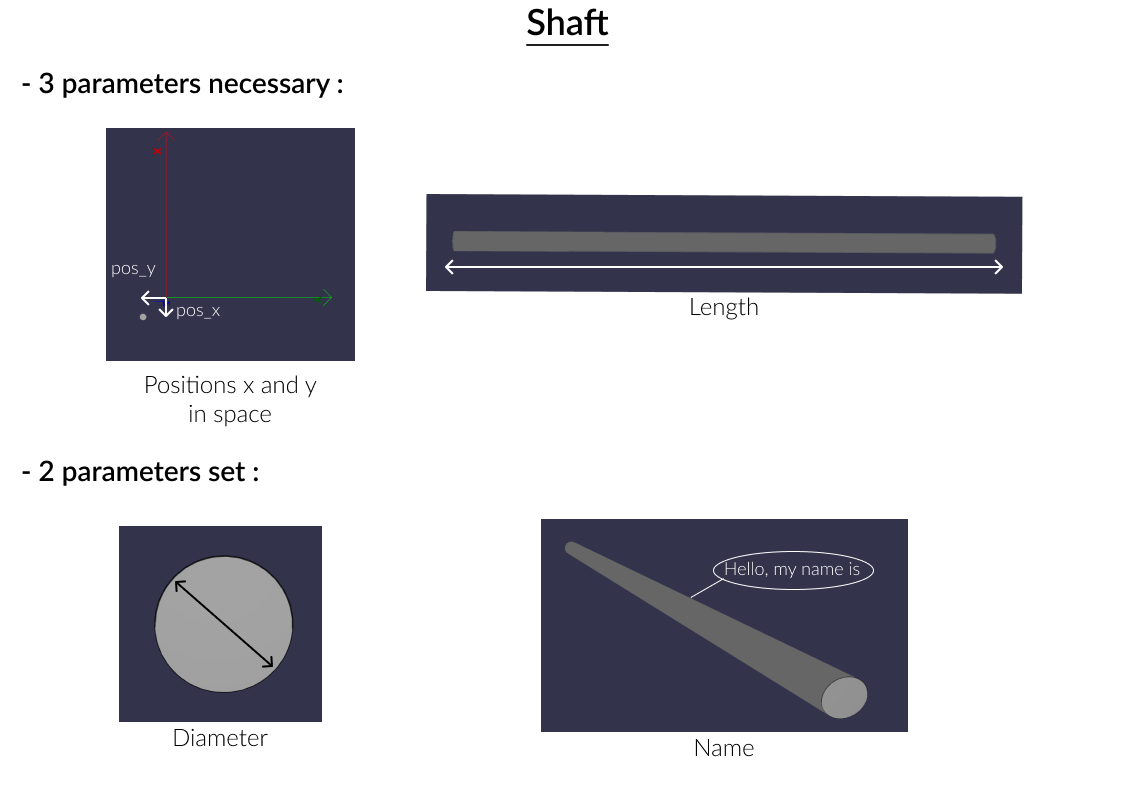

Let's begin with the easiest class which is the shaft. What are the parameters needed to initialize a shaft? In this example, there is the position (pos_x and pos_y), as well as the length and the name. Like all the other classes, the name is not an important argument, so we put the default value to " '' ". The z position is equal to self.length/2 because all the shafts have the same z position in this tutorial. Likewise, they have the same diameter (which is equal to 0.04 but can be changed).

class Shaft(DessiaObject):

def __init__(self, pos_x: float, pos_y: float,length: float, name: str=''):

self.pos_x = pos_x

self.pos_y = pos_y

self.name = name

self.length=length

self.diameter=0.04

self.z_position=self.length/2

DessiaObject.__init__(self,name=name)

The Gear class modelizes one single gear and the diameter along with the length are needed for the initialization. In this tutorial, the number of teeth is not taken into account so the gear's diameter is used to calculate the ratio. The gear is directly linked to the shaft in its initialization through the "shaft" attribute. Another class could have been created in this situation, however that might not be relevant in this user-friendly case. The gear's position is the same as the shaft's (pos_x and pos_y). As for the z position, we consider a uniform distance to separate the shafts, called "offset" in the reductor class. The z_position parameter will store the future position of the gear. It is set to 0 for now.

class Gear(DessiaObject):

def __init__(self, diameter: float, length: float, shaft: Shaft,name: str=''):

self.diameter = diameter

self.length = length

self.name = name

self.shaft = shaft

DessiaObject.__init__(self,name=name)

self.z_position = 0Now let's move on to the motor whose rotation speed is equal to the reductor's input speed. The parameters required for the initialization are the diameter, along with the length and the speed. As well as the gears, the positions will be given by the first shaft in the reductor. The x and y positions are set to 0. As for the z position, the motor is considered to be located at the first shaft's upstream (which always starts at the position 0 of the z axis), so we can set the value to self.length/2 (the position represents the motor's center).

class Motor(DessiaObject):

def __init__(self, diameter: float, length: float, speed: float, name: str = ''):

self.diameter = diameter

self.length = length

self.speed = speed

self.name = name

DessiaObject.__init__(self,name=name)

self.z_position=self.length/2

self.pos_x=0

self.pos_y=0The Mesh represents the connections between two gears. It will connect the shafts in the reductor. Two gears and a name (this one is optional though) are required for the initialization. By the way, the two Gear arguments (gear1 and gear2) could have been replaced by one single list of Gear set as argument. The gears order is important for calculating the ratio. Here, gear1 is the driving gear and gear2 is the driven one.

class Mesh(DessiaObject):

def __init__(self, gear1: Gear, gear2: Gear, name: str=''):

self.gear1 = gear1

self.gear2 = gear2

self.gears = [gear1, gear2]

self.name = name

DessiaObject.__init__(self,name=name)To finish, the Reductor class represents the reductor itself. A Motor, a list of Shaft, a list of Mesh and a name (optional) are required for the instantiation. In fact, the meshes already contain the gears, and the gears are already connected to the shafts. So we don't need to put the meshes in this initialization. The offset parameter is used to characterize the distance between the elements of the shafts.

class Reductor(DessiaObject):

def __init__(self, motor: Motor, shafts:List[Shaft], meshes: List[Mesh], name: str = ''):

self.shafts = shafts

self.meshes = meshes

self.name = name

self.motor = motor

self.offset = 0.02

DessiaObject.__init__(self,name=name)2.2 - Define engineering simulations needed

Volmdlr primitives

In this tutorial, most methods added to the classes are linked to the 3D representation (using volmdlr). Every component is represented by a cylinder towards z axis by using the position parameters. The volmdlr_primitives functions of the Shaft class , the Gear and the Motor are roughly the same.

Shaft:

def volmdlr_primitives(self):

primitives = []

pos = vm.Point3D((self.pos_x, self.pos_y, self.z_position))

axis = vm.Vector3D((0,0,1))

cylinder = p3d.Cylinder(pos, axis, self.diameter/2, self.length)

primitives.append(cylinder)

return primitives

Gear:

def volmdlr_primitives(self):

primitives = []

pos = vm.Point3D((self.shaft.pos_x,self.shaft.pos_y, self.z_position))

axis = vm.Vector3D((0,0,1))

cylinder = p3d.Cylinder(pos, axis, self.diameter/2, self.length)

primitives.append(cylinder)

return primitives

Motor:

def volmdlr_primitives(self):

primitives = []

pos = vm.Point3D((self.pos_x, self.pos_y, self.z_position))

axis = vm.Vector3D((0,0,1))

cylinder = p3d.Cylinder(pos, axis, self.diameter/2, self.length)

primitives.append(cylinder)

return primitivesThe reductor case is a bit different as each one of its elements' z_position is needed. For that, we use the parameter offset and the length of the different elements. At first, we need to plot the motor by using the x and y positions of the first shaft. The z position is already set in the "init" of the motor to self.length/2. If the first shaft is located on z=0, there's no need to change.

def volmdlr_primitives(self):

primitives = []

self.motor.pos_x=self.shafts[0].pos_x

self.motor.pos_y=self.shafts[0].pos_y

primitives.extend(self.motor.volmdlr_primitives())

return primitivesThen, the program looks over the lists of gears and shafts, and plots them all using the right z_position. The order is important, which is why two loops are needed. One for gear1's first shaft meshes and one for gear1's second shaft meshes. Let's keep in mind that two gears of a same mesh have the same z_position. We also need to create a z_previous_position variable for the shaft and the gear to save the z position of the previous browsed element. The variable for the gear is initialized to self.motor.length + self.offset as we already plotted the motor. As for the shaft, the variable is initialized to 0 as the first shaft is located on z=0.

def volmdlr_primitives(self):

primitives = []

self.motor.pos_x=self.shafts[0].pos_x

self.motor.pos_y=self.shafts[0].pos_y

primitives.extend(self.motor.volmdlr_primitives())

z_previous_position_gear = self.motor.length+self.offset

z_previous_position_shaft=0

for shaft in self.shafts:

for mesh in self.meshes:

if mesh.gear1.shaft==shaft:

return primitivesAfter that, in the for loop, half the current gear's length is added to z_previous_position to get the position of the current gear's center. Then, the z_position of the two gears has to be changed and their volmdlr_primitives functions must be called. Finally, as we're moving on to the next gear, z_previous_position_gear is refreshed and takes the current gear center's position.

def volmdlr_primitives(self):

primitives = []

self.motor.pos_x=self.shafts[0].pos_x

self.motor.pos_y=self.shafts[0].pos_y

primitives.extend(self.motor.volmdlr_primitives())

z_previous_position_gear = self.motor.length+self.offset

z_previous_position_shaft=0

for shaft in self.shafts:

for mesh in self.meshes:

if mesh.gear1.shaft==shaft:

z_position = z_previous_position_gear+mesh.gear1.length/2

mesh.gear1.z_position=z_position

mesh.gear2.z_position=z_position

primitives.extend(mesh.gear1.volmdlr_primitives())

primitives.extend(mesh.gear2.volmdlr_primitives())

break

z_previous_position_gear = z_position+mesh.gear2.length/2+self.offset

return primitivesThe last part of the loop focuses on the shafts. Indeed, lengths and z_positions of every shaft have to be changed to prevent them from being disproportionate. We consider that the length of a shaft is equal to the distance between the two gears plus two offsets (on each extremity). As a result, considering the parameters of our system, the length of the shaft is equal to the z position of the previous gear + the length of the gear/2 + the offset - (the z position of the previous gear browsed - the length of the gear/2 - the offset). The part (the z position of the previous gear - the length of the gear/2 - the offset) is stored inside the variable z_previous_position_shaft. As for the z_position of the shaft, it's just the variable z_previous_position_shaft + the length of the shaft /2 . The case of the motor's first shaft is also considered by initializing the z_previous_position_shaft parameter to 0 so that the length of the shaft is equal to the length of the motor + the length of the gear+ 2 offset (there is no offset for the motor) and the z_position is equal to the length/2.

def volmdlr_primitives(self):

primitives = []

self.motor.pos_x=self.shafts[0].pos_x

self.motor.pos_y=self.shafts[0].pos_y

primitives.extend(self.motor.volmdlr_primitives())

z_previous_position_gear = self.motor.length+self.offset

z_previous_position_shaft=0

for shaft in self.shafts:

for mesh in self.meshes:

if mesh.gear1.shaft==shaft:

z_position = z_previous_position_gear+mesh.gear1.length/2

mesh.gear1.z_position=z_position

mesh.gear2.z_position=z_position

primitives.extend(mesh.gear1.volmdlr_primitives())

primitives.extend(mesh.gear2.volmdlr_primitives())

break

shaft.length= z_position+mesh.gear1.length/2+self.offset-z_previous_position_shaft

shaft.z_position=shaft.length/2+z_previous_position_shaft

primitives.extend(shaft.volmdlr_primitives())

z_previous_position_gear = z_position+mesh.gear2.length/2+self.offset

z_previous_position_shaft= z_position-mesh.gear2.length/2-self.offset

return primitivesAt this point, we finally managed to code our functions to get 3D representations. A couple functions are now added to calculate the mass of the different elements such as the gears, the shafts and the reductor. The mass is equal to the volume of the cylinder multiplied by the volumic mass (7500). The reductor's mass is calculated by adding the mass of each gear and each shaft.

Calculation of the mass

Shaft:

def mass(self):

return 7500 *math.pi*self.length*(self.diameter/2)**2Gear:

def mass(self):

return 7500 *math.pi*self.length*(self.diameter/2)**2Reductor:

def mass(self):

mass = 0

for shaft in self.shafts:

mass += shaft.mass()

for meshe in self.meshes:

for gear in [meshe.gear1, meshe.gear2]:

mass += gear.mass()

return massComputation of the speed output

To finish, the last function computes the output speed of the reductor. The idea is to go through the list of meshes and multiply the input speed by each ratio.

def speed_output(self):

output_speed=self.motor.speed

for mesh in self.meshes:

output_speed = output_speed*mesh.gear1.diameter/mesh.gear2.diameter

return output_speed

2.3 - Create elementary generator & optimizer

Create a class Optimizer

After coding all these classes and methods, we can make up our minds on how to optimize a reductor. First of all, let's add a new class called "Optimizer" in the core.py file. This class takes the reductor and every requirement the system is expected to meet as inputs. In our case, those are the speed_output and the box limitation. The box limitation is defined by the two tuples x_min_max and y_min_max.

class Optimizer(DessiaObject):

def __init__(self, reductor: Reductor, speed_output: float, x_min_max: Tuple[float, float], y_min_max: Tuple[float, float], name: str =''):

self.reductor = reductor

self.x_min_max = x_min_max

self.y_min_max = y_min_max

self.speed_output = speed_output

DessiaObject.__init__(self,name=name)

How to optimize?

The optimization is done by the "minimize" function imported from scipy.optimize. This function returns the arguments needed to minimize an objective function based on several criteria and conditions, using the gradient descend procedure. A good optimization relies on a "good" objective function. The closer to 0 the objective function, the better the optimization, the better the reductor meets its requirements. You can see the inputs and outputs of this function on this link (https://docs.scipy.org/doc/scipy/reference/generated/scipy.optimize.minimize.html (opens in a new tab)).

Defining the x vector

The "minimize" function needs a x vector that specifies the parameters to optimize. In our tutorial, those are the x and y positions of every shaft and the diameter of one gear in all the meshes. The two gears are not needed as arguments as the diameter of the second gear is deduced from the first gear's diameter and the shaft. As a result, the vector x is composed of 8 elements, the 6 first are the positions x and y of the 3 shafts and the 2 last are the diameters of the 2 meshes' first gears.

Defining the bounds of the optimization

We also have to create a "bounds" vector to bound (define min and max) of all the parameters of the x vector. In our case, the minimum and the maximum of the shaft's x and y positions are the parameters x_min_max and y_min_max. As for the two gears' diameters, the shaft's diameter is taken as the minimum and the diagonal of the box as the maximum. This bounds vector will be initialized in the "init" because we need it to use the "minimize" function but also to create an initialization vector.

def __init__(self, reductor: Reductor, speed_output: float, x_min_max: Tuple[float, float], y_min_max: Tuple[float, float], name: str =''):

self.reductor = reductor

self.x_min_max = x_min_max

self.y_min_max= y_min_max

self.speed_output = speed_output

DessiaObject.__init__(self,name=name)

bounds = []

for shaft in reductor.shafts:

bounds.append([x_min_max[0], x_min_max[1]])

bounds.append([y_min_max[0], y_min_max[1]])

for mesh in reductor.meshes:

bounds.append([mesh.gear1.shaft.diameter, ((y_min_max[1]-y_min_max[0])**2 + (x_min_max[1]-x_min_max[0])**2)**(1/2)])

self.bounds = boundsHow to choose and construct the initial conditions of an optimization?

The last parameter needed to use the "minimize" function is an initial x vector. This parameter is very important because the result of the optimization depends on it. Two optimizations can have different results if their initial vectors are different. A good pratice is to always create a function that builds the initial vector as settling the best one is sometimes tricky. This function calculates an "acceptable" initial vector from the random one by making it converging to an "acceptable" vector after each loop.

In this tutorial, the "random" function of numpy's "random" module is used. The command float(npy.random.random(1)) returns a random number between 0 and 1. We just have to multiply this random number by the difference between the min and the max of the bounds and add the minimum for all the bounds to construct our initialization vector.

def cond_init(self):

x0 = []

for interval in self.bounds:

x0.append((interval[1]-interval[0])*float(npy.random.random(1))+interval[0])

return x0Construct an update function in your objects

Now, let's build the objective function. The only rule is to set the x vector as its first input.

As for the function's body, the first thing to do is updating the reductor's parameters with the x vector. These parameters will change during the optimization. When a method from the reductor class is called, you have to make sure your object is up-to-date, ie is updated with the newest x vector.

This update function will be coded in the reductor class. The input of this function is the x vector, and we just have to assign the parameters of this vector to the right objects and arguments. The 6 first parameters are the x and y positions of the shafts, in their respective order. The 2 last are the meshes first gear's diameters, in their respective order too. The diameters of the other gears and meshes are deduced from their their centers' distances.

def update(self, x):

i=0

for shaft in self.shafts:

shaft.pos_x=x[i]

shaft.pos_y=x[i+1]

i+=2

for mesh in self.meshes:

shaft_gear1=mesh.gear1.shaft

shaft_gear2=mesh.gear2.shaft

center_distance = ((shaft_gear1.pos_x-shaft_gear2.pos_x)**2+(shaft_gear1.pos_y-shaft_gear2.pos_y)**2)**(1/2)

mesh.gear1.diameter = x[i]

mesh.gear2.diameter = (center_distance-x[i]/2)*2

i += 1

Build the objective function and add a speed specification in the optimization

Now, let's set up the specifications that the reductor is going to meet. Just as a reminder, the optimization is done when the objective function reaches a value near 0. So we just need to substract the current speed (calculated by the reductor's function) from the objective speed (the one in the Optimizer's init) and add the result to the parameter that objective function returns. In the tutorial, we call this parameter "functional", and this parameter must be always positive. If functional <0, the optimization fails.

Another thing that you can add to the condition check is a power/an exponent. The higher the power, the more important the slope of the function, the quicker the "minimize" function will find an optimized result. In this tutorial, we chose to add a power of 2 to the operations but this is something you can change.

def objective(self, x):

self.reductor.update(x)

speed = self.reductor.speed_output()

functional = 0

functional += (self.speed_output- speed)**2

return functional

Construct an optimization into a function

For now, let's do a test using this condition in the objective function. Before that, we have to create an "optimize" function in the optimizer class that calls the "minimize" function but also the while loop with the initialization vector that we randomly choose (the function cond_init). This step, which consists in choosing the conditions, is a milestone that determines whether the optimization will be successful or not. The "success" output of the "minimize" function helps us know if the optimization encountered problems or not. Moreover, a "precision" parameter has to be set (which corresponds to the "fun" parameter of the resulting object). In our case there is only one specification, and we can say that an optimization is successful if the objective result is inferior to 1e-5 (the smaller the precision, the longer it takes to process the optimization).

Furthermore, a "max_loops" parameter is added, in case the precision is too small and the "success" is too hard to reach.

Finally, when an optimized result is found, the x vector has to be updated one last time. Otherwise, the current x vector might not be the finest one.

def optimize(self, max_loops=1000):

valid = True

count = 0

while valid and count < max_loops:

x0 = self.cond_init()

self.reductor.update(x0)

res = minimize(self.objective, x0, bounds=self.bounds)

count += 1

if res.fun<1e-5 and res.success:

self.reductor.update(res.x)

valid = False

return self.reductor

return self.reductorScript

For the test, we have to code a script in another file called "scripts.py". In this file, you have to create a reductor object, use it to initialize an optimizer object and launch the optimize function. The diameters values are not important because they will change during the optimization. (We set it to 0 and 0.1). You can choose whatever you want as inputs of the motor and the specifications parameters of the optimizer.

import objects.core as objects

motor = objects.Motor(diameter=0.1, length=0.2, speed=120)

shafts = [objects.Shaft(pos_x=0, pos_y=0, length=0.1), objects.Shaft(pos_x=0, pos_y=0, length=0.1),

objects.Shaft(pos_x=0, pos_y=0, length=0.1)]

meshes = []

for j, shaft in enumerate(shafts) :

if j == 1:

gear1 = objects.Gear(diameter=0.1, length=0.01, shaft=shaft)

gear2 = objects.Gear(diameter=0.1, length=0.01, shaft=shaft)

meshes.append(objects.Mesh(gear, gear1))

else:

gear = objects.Gear(diameter=0.1, length=0.01, shaft=shaft)

meshes.append(objects.Mesh(gear2, gear))

reductor = objects.Reductor(motor, shafts, meshes)

optimizer = objects.Optimizer(reductor=reductor, speed_output=500, x_min_max=[-1,1], y_min_max=[-1,1])

optimizer.optimize()

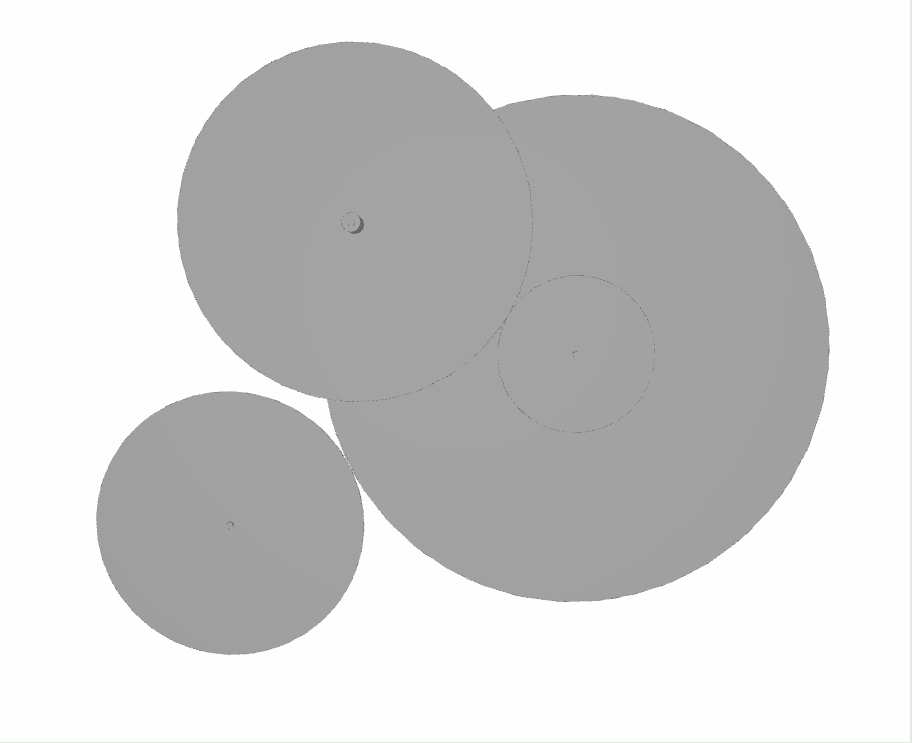

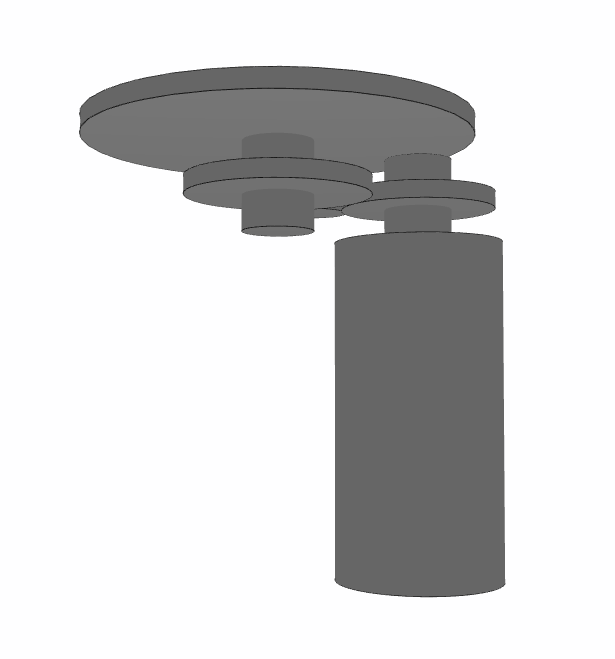

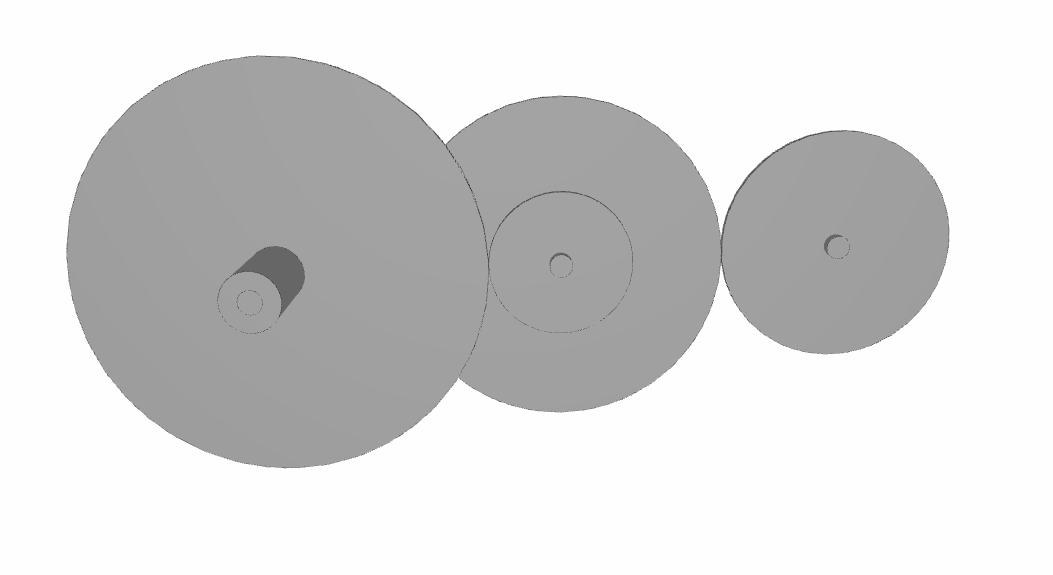

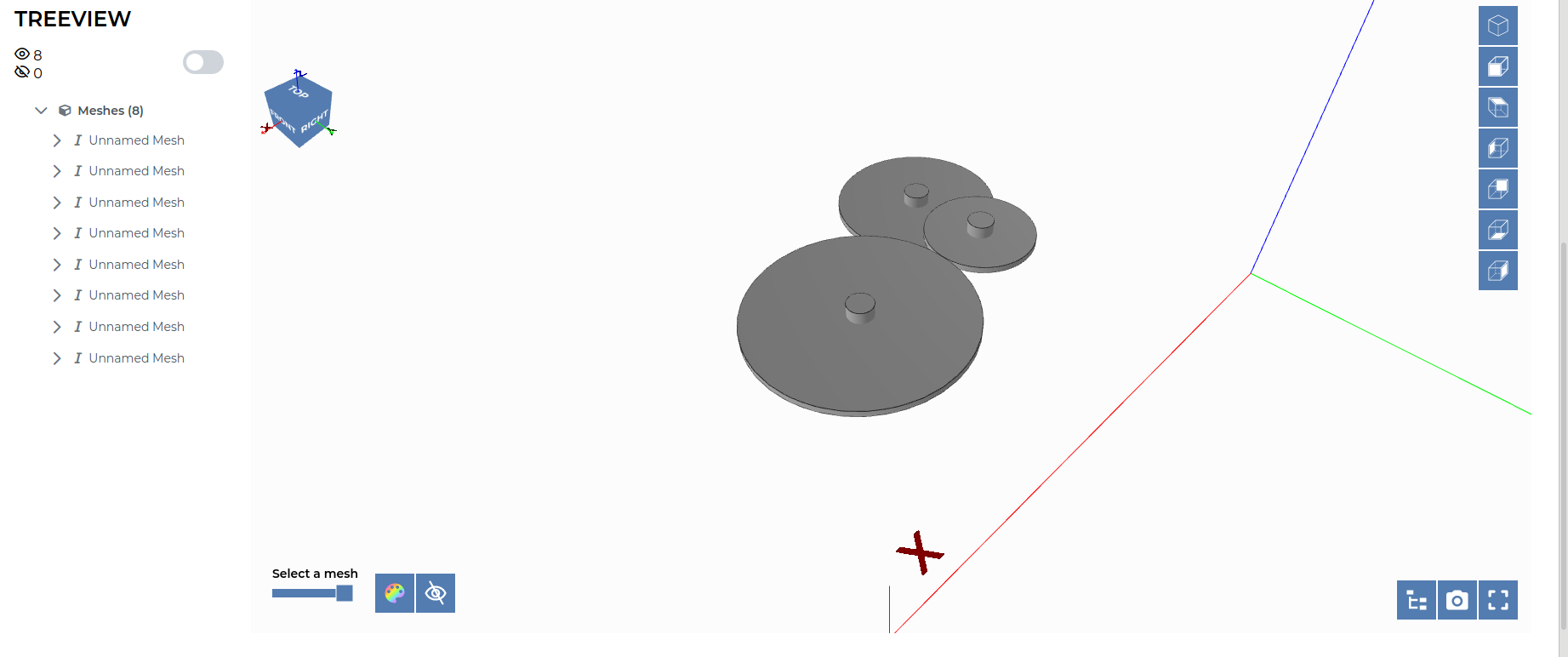

If you run this script, and use the function babylonjs on the reductor to show his 3D representation, you'll get this kind of result :

- In the console, type : reductor.babylonjs()

Adding a position specification

By calling the reductor's speed_output function, you can easily check that the speed condition is verified. However, you'll notice that the gears are way too big, which is not surprising since the box limits have not been set as specifications in the objective function.

In order to do that, we have to verify for each gears if their positions + their diameters/2 are inside the box. If a gear is outside of the box, we add the difference between the limit of the box and the position + the diameter/2 of the gear to the functional variable (raised to the power 2). We have to do that for all the borders of the box (one condition for each borders).

def objective(self, x):

self.reductor.update(x)

speed = self.reductor.speed_output()

functional = 0

functional += (self.speed_output- speed)**2

for mesh in self.reductor.meshes:

for gear in [mesh.gear1,mesh.gear2]:

if gear.shaft.pos_x-gear.diameter/2 < self.x_min_max[0]:

functional += (gear.shaft.pos_x-gear.diameter/2-self.x_min_max[0])**2

if gear.shaft.pos_x+gear.diameter/2 > self.x_min_max[1]:

functional+= (gear.shaft.pos_x-gear.diameter/2-self.x_min_max[1])**2

if gear.shaft.pos_y-gear.diameter/2 < self.y_min_max[0]:

functional += (gear.shaft.pos_y-gear.diameter/2-self.y_min_max[0])**2

if gear.shaft.pos_y+gear.diameter/2 > self.y_min_max[1]:

functional += (gear.shaft.pos_y-gear.diameter/2-self.y_min_max[1])**2

return functional

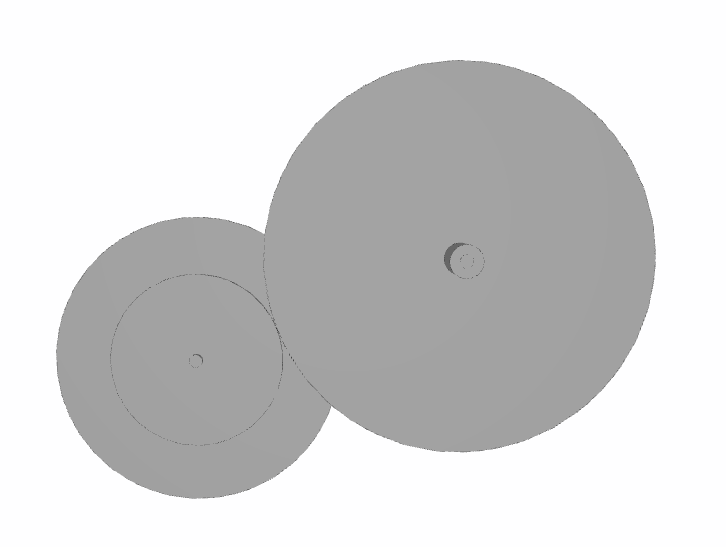

After modifying the objective function, you can try running the script again. Normally, the size of the gears are reasonable now.

Adding an optimization on the mass

The box conditions are satisfied now, the last specification that we have to add is the mass optimization. For that, we just have to add the mass to the functional variable. However, this time we add a real parameter to the functional variable and not a difference. The mass parameter will never be equal to 0. The objective is to find the smallest value. Moreover, this parameter can interfere with the other specifications in the objective function. If this parameter is too high, the optimization will reduce this parameter without taking into account of the other conditions. But if this parameter is too small, the optimization might lack precision. As we are facing a dilemma, the specifications have to be sorted in the range of importance. In this tutorial, we chose to put the mass specification first, that's why we only added 1/10 of the mass to functional variable. You can try another distribution of importance between the specifications by dividing by another value.

def objective(self, x):

self.reductor.update(x)

speed = self.reductor.speed_output()

functional = 0

functional += (self.speed_output- speed)**2

for mesh in self.reductor.meshes:

for gear in [mesh.gear1,mesh.gear2]:

if gear.shaft.pos_x-gear.diameter/2 < self.x_min_max[0]:

functional += (gear.shaft.pos_x-gear.diameter/2-self.x_min_max[0])**2

if gear.shaft.pos_x+gear.diameter/2 > self.x_min_max[1]:

functional+= (gear.shaft.pos_x-gear.diameter/2-self.x_min_max[1])**2

if gear.shaft.pos_y-gear.diameter/2 < self.y_min_max[0]:

functional += (gear.shaft.pos_y-gear.diameter/2-self.y_min_max[0])**2

if gear.shaft.pos_y+gear.diameter/2 > self.y_min_max[1]:

functional += (gear.shaft.pos_y-gear.diameter/2-self.y_min_max[1])**2

functional += self.reductor.mass()/10

return functional

Also, the precision might be changed to prevent the algorithm from taking too much time to run, since only 1/10 of the mass is added after each incrementation. Choosing the precision parameter might be difficult, which is why it will be determined by the computer through an algorithm that takes into account the specifications and the box limits.

def optimize(self, max_loops=1000):

valid = True

count = 0

while valid and count < max_loops:

x0 = self.cond_init()

self.reductor.update(x0)

res = minimize(self.objective, x0, bounds=self.bounds)

count += 1

if res.fun < 10 and res.success:

print(count)

self.reductor.update(res.x)

valid = False

return res

return res

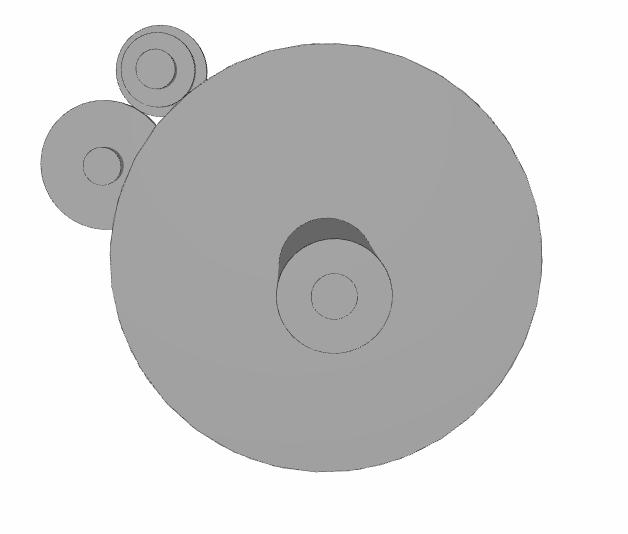

If you run the script again, you will see that the size of the gear is smaller now.

Other examples of adding a specification

Now, all the specifications are met by the objective function. However, there are still some minor issues. For example, you can have the following type of problem where the diameter of the mesh's second gear is inferior to the diameter of the shaft:

It's not a surprise as we have bounded the mesh first gear's diameter only. To solve this problem, we can add a condition in the objective function. In that case, it would not be a matter of reaching an objective, but something that the optimizer doesn't do. Thus, we can add a fixed value to the "functional" variable as long as the condition isn't verified, which is equal to 10 in our example. This will avoid the solutions from having this kind of issue.

def objective(self, x):

self.reductor.update(x)

speed = self.reductor.speed_output()

functional = 0

functional += (self.speed_output- speed)**2

for mesh in self.reductor.meshes:

if mesh.gear2.diameter<mesh.gear2.shaft.diameter:

functional += 10

for gear in [mesh.gear1,mesh.gear2]:

if gear.shaft.pos_x-gear.diameter/2 < self.x_min_max[0]:

functional += (gear.shaft.pos_x-gear.diameter/2-self.x_min_max[0])**2

if gear.shaft.pos_x+gear.diameter/2 > self.x_min_max[1]:

functional+= (gear.shaft.pos_x-gear.diameter/2-self.x_min_max[1])**2

if gear.shaft.pos_y-gear.diameter/2 < self.y_min_max[0]:

functional += (gear.shaft.pos_y-gear.diameter/2-self.y_min_max[0])**2

if gear.shaft.pos_y+gear.diameter/2 > self.y_min_max[1]:

functional += (gear.shaft.pos_y-gear.diameter/2-self.y_min_max[1])**2

functional += self.reductor.mass()/10

return functional

The optimizer is done now, but you can still go further and add some additional conditions to the objective function. For example, you can try to avoid collisions between shafts and gears. In our tutorial, the distance between shafts is set avoid collisions but changing lengths may create this kind of problems in some solutions:

Provided that you deeply understood how the optimization works and how the objects are structured, that may be a good exercise. In addition, all the solutions will be collision-free.

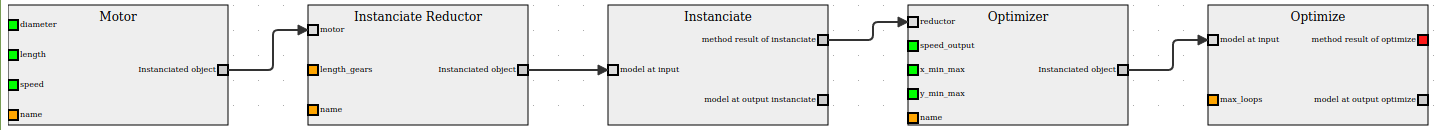

2.4 - Build your workflow

Create a workflow for an optimizer

This part is about building a good workflow from the optimizer. The first step consists in transforming the Optimizer object into workflow blocks.

import tuto_power_transmission.core as objects

import dessia_common.workflow as wf

block_optimizer= wf.InstanciateModel(objects.Optimizer, name='Optimizer')

method_optimize = wf.MethodType(class_=objects.Optimizer, name='optimize')

block_optimize= wf.ModelMethod(method_type=method_optimize, name='Optimize')Next, a reductor is needed for the optimization. However, instantiating all the gears and shafts is neither convenient, nor in the workflow's logic. Moreover, all the diameters and lengths are determined in the optimizer. Therefore, the only parameters that the user needs to choose are the motor and the optimizer's parameters as well as the length of the gears. Thus, a good way to overcome this problem to create an InstantiateReductor class that only needs a motor and a gear length to instantiate a reductor. Its "instanciate" method returns a reductor by automatically creating all the gears, meshes and shafts. This improvement makes the workflow much more user-friendly.

class InstanciateReductor(DessiaObject):

def __init__(self,motor: Motor, length_gears: float = 0.01, name: str = ''):

self.motor=motor

self.length_gears=length_gears

DessiaObject.__init__(self,name=name)

def instanciate(self):

shafts = [Shaft(pos_x=0, pos_y=0, length=0.1), Shaft(pos_x=0, pos_y=0, length=0.1),

Shaft(pos_x=0, pos_y=0, length=0.1)]

meshes = []

for j, shaft in enumerate(shafts) :

if j == 1:

gear1 = Gear(diameter=0.1, length=self.length_gears, shaft=shaft)

gear2 = Gear(diameter=0.1, length=self.length_gears, shaft=shaft)

meshes.append(Mesh(gear, gear1))

else:

gear = Gear(diameter=0.1, length=self.length_gears, shaft=shaft)

meshes.append(Mesh(gear2, gear))

reductor = Reductor(self.motor, shafts, meshes)

return reductorNow, let's create the workflow blocks for the "InstanciateReductor" class and for the "InstanciateModel" method.

block_instanciate_reductor = wf.InstanciateModel(objects.InstanciateReductor, name='Instanciate Reductor')

method_instanciate = wf.MethodType(class_=objects.InstanciateReductor, name='instanciate')

block_instanciate = wf.ModelMethod(method_type=method_instanciate, name='Instanciate')

A motor has to be instiantiated as well, thus needs a specific workflow block.

block_motor=wf.InstanciateModel(objects.Motor, name='Motor')

At this point, the only step remaining is to create the workflow and to connect them.

block_workflow=[block_optimizer,block_optimize,block_instanciate_reductor,block_instanciate,block_motor]

pipe_worflow=[wf.Pipe(block_optimizer.outputs[0], block_optimize.inputs[0]),

wf.Pipe(block_instanciate_reductor.outputs[0], block_instanciate.inputs[0]),

wf.Pipe(block_motor.outputs[0], block_instanciate_reductor.inputs[0]),

wf.Pipe(block_instanciate.outputs[0], block_optimizer.inputs[0])]

workflow= wf.Workflow(block_workflow,pipe_worflow,block_optimize.outputs[0])Running the code and plotting the workflow using "workflow.plot_jointjs()" should display the following result:

As for the inputs values of the workflow, the "optimizer" block has 3 inputs (1: speed_output, 2: x_min_max, 3: y_min_max), the "instanciate_reductor" block has 1 input (1: length of the gears) and the "motor" block has 3 inputs (0: diameter, 1: length, 3: speed_input).

input_values = {workflow.index(block_optimizer.inputs[1]): 500,

workflow.index(block_optimizer.inputs[2]): [-1,1],

workflow.index(block_optimizer.inputs[3]): [-1,1],

workflow.index(block_instanciate_reductor.inputs[1]): 0.01,

workflow.index(block_motor.inputs[0]): 0.1,

workflow.index(block_motor.inputs[1]): 0.2,

workflow.index(block_motor.inputs[2]): 150

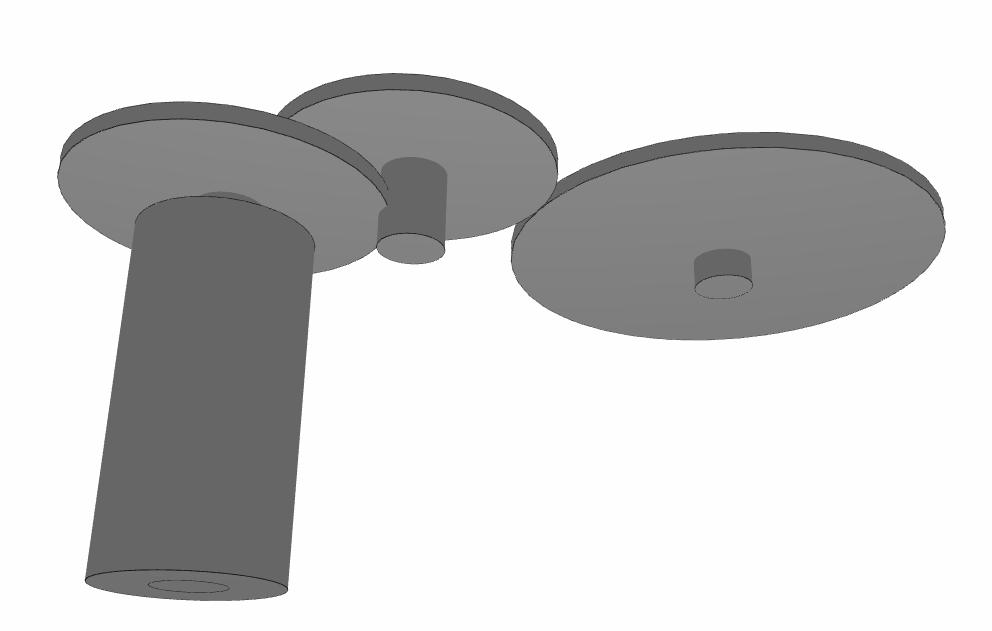

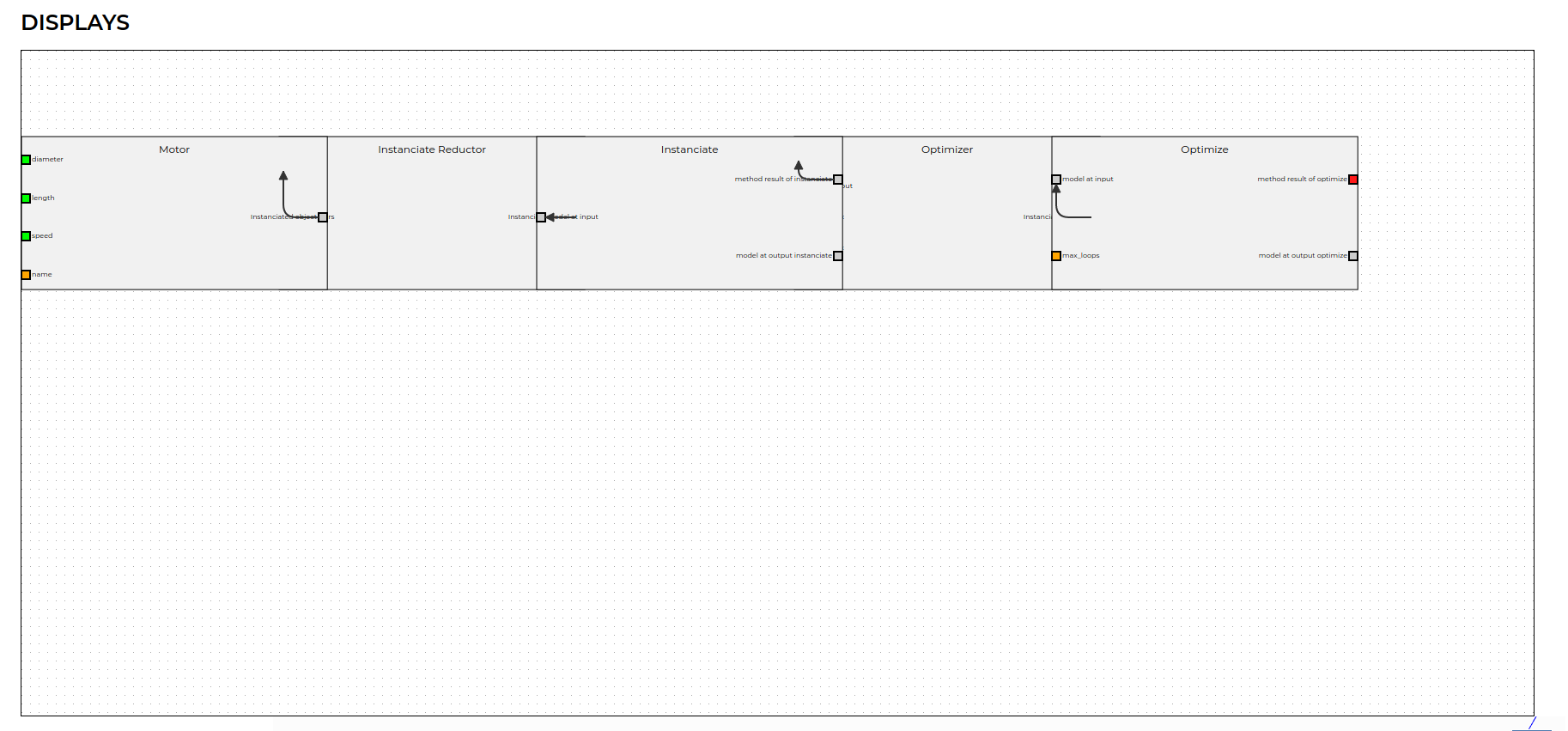

}If you run the workflow, you should get a reductor in result. If the platform runs, you can also import the workflow run to see its plot on the platform. The reductor's "standalone_in_db" attribute must be True.

from dessia_api_client import Client

workflow_generator_run = workflow.run(input_values)

c = Client(api_url = 'https://api.platform-dev.dessia.tech')

r = c.create_object_from_python_object(workflow_generator_run)

Here is the result on the platform:

Plot more solutions in an optimizer

The workflow is on top of the page and the optimization on the bottom. In this example, there is only one optimized solution in the output. A few changes in the code are needed in order to compare the different optimizations.

Firstly, we need to change the return of the optimize method. We remove the first return in the while loop and replace it by an add of a deep copy of the reductor in a list list_reductor, that we defined at the beginning of the method. The last return will now return the list_reductor and not just the reductor. The optimize function return now a list of solutions optimized.

First of all, the output of the "optimize" method has to change.

def optimize(self, max_loops: int =1000):

valid = True

count = 0

list_reductor=[]

while valid and count < max_loops:

x0 = self.cond_init()

self.reductor.update(x0)

res = minimize(self.objective, x0, bounds=self.bounds)

count += 1

if res.fun<10 and res.success:

print(count)

self.reductor.update(res.x)

list_reductor.append(copy.deepcopy(self.reductor))

return list_reductor

Add parameters to compare the results of an optimization

Secondly, a few parameters are needed to compare these solutions. This may be the mass, which has already been calculated. But it needs to be declared as the Reductor class' attribute. That's why a new "mass_reductor" attribute is introduced. It stores the mass() method's output. This parameter has to get updated when using the optimizer.

class Reductor(DessiaObject):

_standalone_in_db=True

def __init__(self, motor: Motor, shafts:List[Shaft], meshes: List[Mesh], name: str = ''):

self.shafts = shafts

self.meshes = meshes

self.name = name

self.motor = motor

self.offset = 0.02

DessiaObject.__init__(self,name=name)

self.mass_reductor=self.mass()def update(self, x):

i=0

for shaft in self.shafts:

shaft.pos_x=x[i]

shaft.pos_y=x[i+1]

i+=2

for mesh in self.meshes:

shaft_gear1=mesh.gear1.shaft

shaft_gear2=mesh.gear2.shaft

center_distance = ((shaft_gear1.pos_x-shaft_gear2.pos_x)**2+(shaft_gear1.pos_y-shaft_gear2.pos_y)**2)**(1/2)

mesh.gear1.diameter = x[i]

mesh.gear2.diameter = (center_distance-x[i]/2)*2

i += 1

self.mass_reductor=self.mass()At your convenience, you can add other parameters to compare these solutions. Another parameter that we add is number_solution, equal to the position of the reductor in list_reductor. That will help have a good plot of the solutions in the ParallelPlot display. To do so, we add the attribute to init and update it in the optimize method.

The number of displayed solutions may also be an interesting parameter as it prevents the plot from displaying too much solutions. Let's define a parameter named "number_solution" and add it to the "optimize" function.

class Reductor(DessiaObject):

_standalone_in_db=True

def __init__(self, motor: Motor, shafts:List[Shaft], meshes: List[Mesh], number_solution: int = 0,name: str = ''):

self.shafts = shafts

self.meshes = meshes

self.name = name

self.motor = motor

self.offset = 0.02

self.number_solution=number_solution

DessiaObject.__init__(self,name=name)

self.mass_reductor=self.mass()def optimize(self, max_loops: int =1000):

valid = True

count = 0

list_reductor=[]

while valid and count < max_loops:

x0 = self.cond_init()

self.reductor.update(x0)

res = minimize(self.objective, x0, bounds=self.bounds)

count += 1

if res.fun<10 and res.success:

print(count)

self.reductor.update(res.x)

self.reductor.number_solution=len(list_reductor)

list_reductor.append(copy.deepcopy(self.reductor))

return list_reductorConstruct a parallel plot for optimization

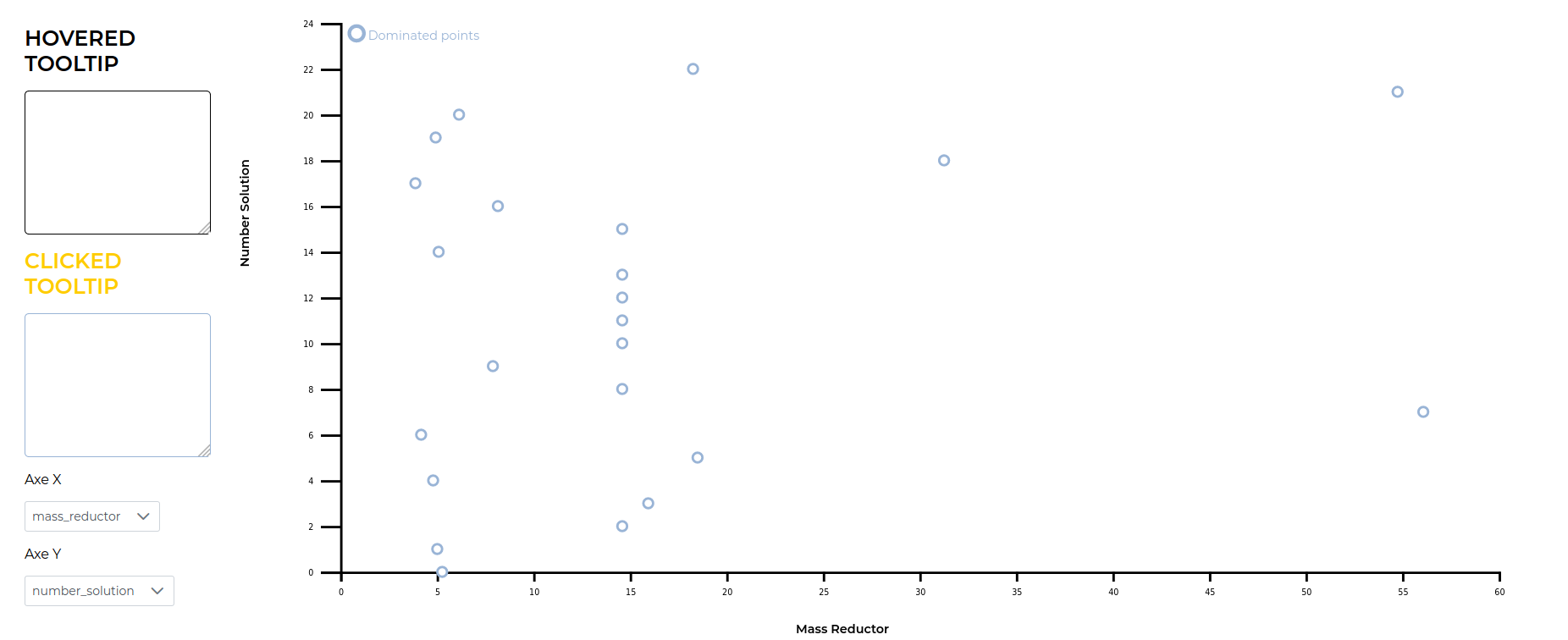

Parameters "mass" and "number_solution" are added in "list_attributes" to get the corresponding block in our workflow.

list_attribute1=['mass_reductor','number_solution']

display_reductor=wf.ParallelPlot(list_attribute1,1,name='Display Reductor')

block_workflow=[block_optimizer,block_optimize,block_instanciate_reductor,block_instanciate,block_motor,display_reductor]

pipe_worflow=[wf.Pipe(block_optimizer.outputs[0], block_optimize.inputs[0]),

wf.Pipe(block_instanciate_reductor.outputs[0], block_instanciate.inputs[0]),

wf.Pipe(block_motor.outputs[0], block_instanciate_reductor.inputs[0]),

wf.Pipe(block_instanciate.outputs[0], block_optimizer.inputs[0]),

wf.Pipe(block_optimize.outputs[0], display_reductor.inputs[0])]

workflow= wf.Workflow(block_workflow,pipe_worflow,block_optimize.outputs[0])If you run the code again and import your WorkflowRun in the platform, you'll get a similar display, where you can easily compare the mass of the different optimized solutions:

If you run the script again and import the workflow run in the platform, here's the result you should have. In this representation, the masses of the different optimized solutions are easier to compare.

This tutorial now comes to an end, and you should have all the capacities to created your future bot.